- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

1. For sintering or curing Teflon/PTFE products, such as Teflon parts, plate, bar and powder coating pipes/valves etc.

2. Max working temperature: 450 ℃ (adjustable)

3. Temperature control accuracy: ±1 ℃

4. Heat source: electricty or gas

5. Different racks and inert gas ovens are available

With many year's experiences, we design, manufacturer and trade good quality industrial PTFE / Teflon sintering /curing ovens with affordable prices.

Our batch ovens are designed to heat up to 450 ℃ for sintering or curing Teflon/PTFE products, such as Teflon parts, plate, bar and powder coating pipes/valves etc. The part(s) to be heated are brought into the oven in batches on racks, carts, or trucks. Production requirements can accommodate manual or automated loading. Standard batch ovens are offered in many sizes, with multiple options available upon request. And we also supply custom engineered batch ovens.

|  |

1. Robust drying chamber: Welded structural steel framework for overall support

2. Temperature uniformity: Typically the airflow within the heated chamber is designed with a recirculating horizontal cross-flow. They can also be equipped with a combination airflow pattern, top-down or bottom-up airflow pattern to guarantee temperature uniformity.

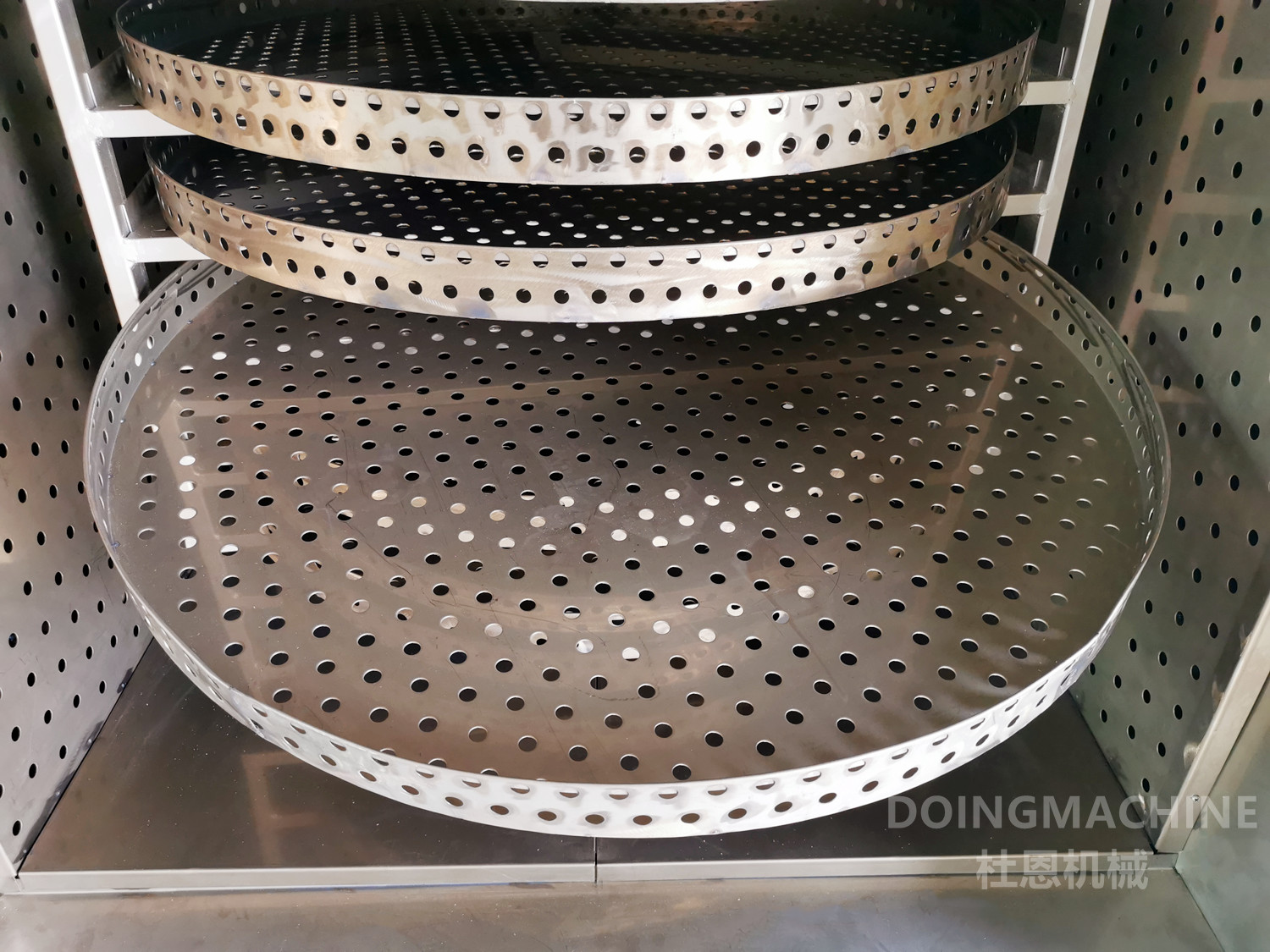

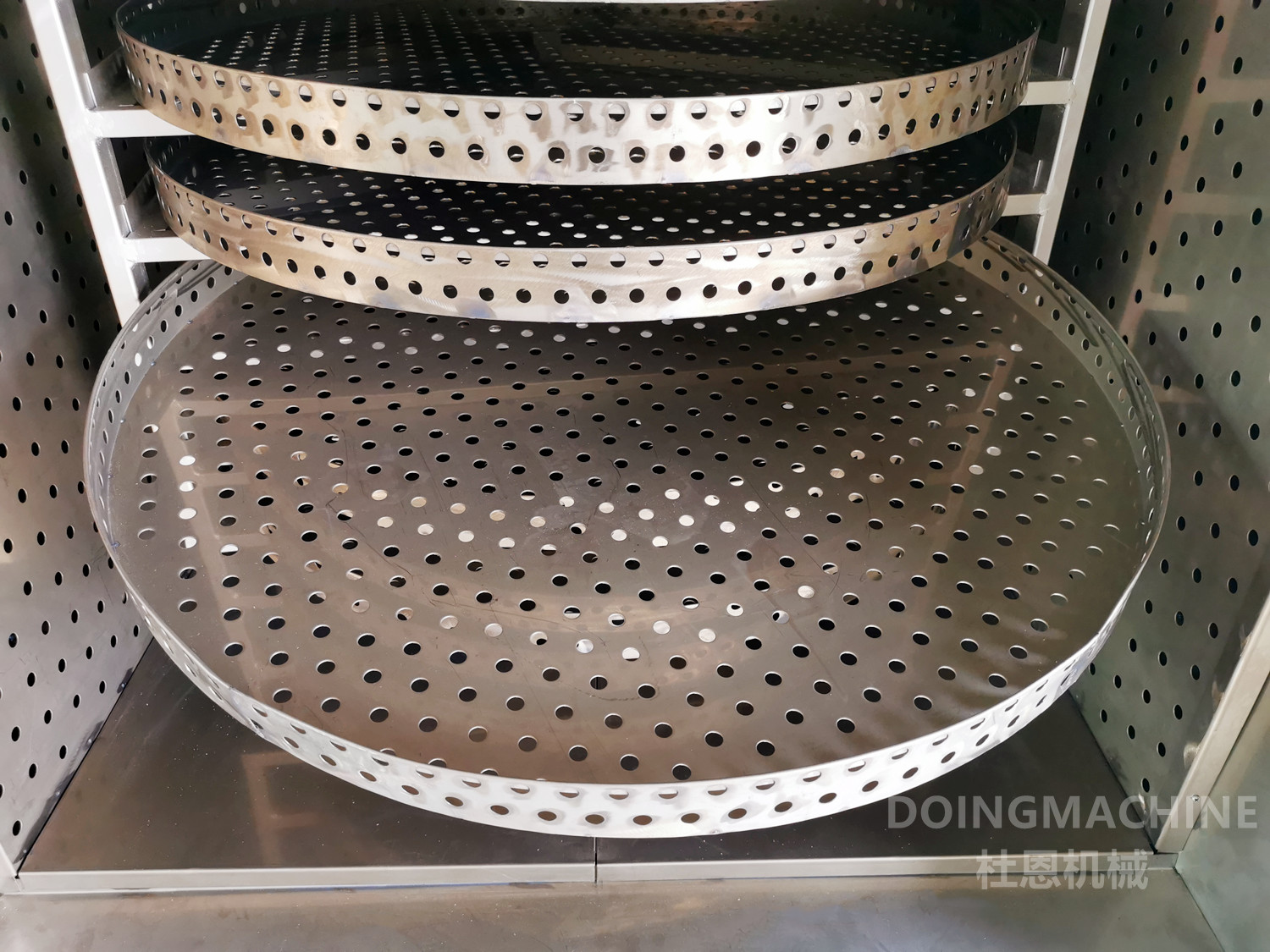

3. Rotary rack/shelf: Specially designed rotary rack/Shelf for Teflon parts can considerably increase heating uniformity.

4. Flexibility in heat source: Our batch ovens offer various heating methods, including gas, electric, infrared, and radiant heating systems.

5. Flexibility in operation: Numerous flooring options are available such as recessed tracks to accommodate product carts, a steel plate floor, or an insulated floor without tracks. Doors can be designed to accommodate any requirement and range from simple horizontal swing doors to pneumatic or hydraulic vertical doors with manual or automatic operation.

6. Easy and accurate control: Simple digital controls for basic operation or PLC controls for complex requirements

| Main specification | ||||

| Oven working space | Standard size or as per client requirement | |||

| Construction material | Mild steel; SUS304/316 or any | |||

| Working temp. range | Ambient+10 to 450 ℃ | |||

| Air-flow pattern | Horizontal / Vertical / combination | |||

| Temp. control accuracy | ±1℃ | |||

| Temp. uniformity | ±2℃ | |||

| Heat-up rate | RT-400 ℃ in 30 minutes | |||

| Timer | Digital pre-settable HS48S-99.99 | |||

| Paint | Enamel paint / Epoxy coating / powder coated | |||

| Power supply | 240V/380V/415V; 50Hz/60Hz; 3 phase | |||

| Heating elements | sheathed heating elements / SS tube | |||

| Insulation | Ceramic wool | |||

| Door seal gasket | Fibre glass rope | |||

| Heavy-duty rack/cart/tray | Designed according to product size, quantity and working condition | |||

| Exhaust manual or automatic | Automatic forced exhaust system with fresh air inlet Manually adjustable damper with fresh air inlet | |||

| Heat source | Electric or gas | |||

| Temperature control | PID with SSR/SCR for high accuracy With 40 programable heat-up rates | |||

| Temperature recorder (Optional) | Microprocessor chip-based paper less, multi-stage temp. indicator cum recorder | |||

| PLC with HMI ( Optional) | PLC can be provided for automation and integration of the whole system, data feeding, process display and fault indication can be seen in HMI | |||

| SCADA system (Optional) | High quality integration and controlling system from one point can be done with SCADA | |||

| Door (Optional) | 1) Door interlocked with fan and heater for safty 2) Doors on both ends 3) Vertical lift door | |||

| Windows and lights | 1) Viewing window 2) Interior light and access ports for calibration | |||

| Timer and alarm | 1) 24/7 timer 2) APT/AD16 audible / visual alarm indicators | |||

Rotary discs

Rotary tray

Inert gas oven

Heavy-duty rack with rail

PTFE Parts

PTFE plates

PTFE bars

A: Our Sintering oven can be customerized. Before we can work out a detailed quotation, we have to know the following information:

1) Type of heat process: drying, preheating, curing, sintering, forming, aging etc.

2) Product name, size, weight, quantity

3) Max temperature, heat-up rate, temperature uniformity

4) Construction material

5) Heat source

A: The dryer is packed in plywood box for shipping

A: We have the following standard models:

| Model | TY151-1 | TY-151-2 | TY-151-3 | TY-151-4 |

| Working space mm | 800X800X1000 | 1000X1000X1000 | 1200X1200X1100 | 1400X1400X1000 |

| Overall dimension mm | 1100X1560X1800 | 1300X1760X1800 | 1500X1960X1900 | 1700X2160X1900 |

| Tray diameter mm | 700 | 900 | 1100 | 1200 |

| Supply Voltage V | 240/380/415V | 240/380/415V | 240/380/415V | 240/380/415V |

| Electrical heater KW | 14 | 16 | 18 | 20 |

| Working temp. ℃ | RT+10 - 450 | RT+10 - 450 | RT+10 - 450 | RT+10 - 450 |

| Temp. control accucary ℃ | ±1 | ±1 | ±1 | ±1 |

| Circulation fan KW | 0.75 x2 | 0.75 x2 | 0.75 x2 | 0.75 x2 |

1. For sintering or curing Teflon/PTFE products, such as Teflon parts, plate, bar and powder coating pipes/valves etc.

2. Max working temperature: 450 ℃ (adjustable)

3. Temperature control accuracy: ±1 ℃

4. Heat source: electricty or gas

5. Different racks and inert gas ovens are available

With many year's experiences, we design, manufacturer and trade good quality industrial PTFE / Teflon sintering /curing ovens with affordable prices.

Our batch ovens are designed to heat up to 450 ℃ for sintering or curing Teflon/PTFE products, such as Teflon parts, plate, bar and powder coating pipes/valves etc. The part(s) to be heated are brought into the oven in batches on racks, carts, or trucks. Production requirements can accommodate manual or automated loading. Standard batch ovens are offered in many sizes, with multiple options available upon request. And we also supply custom engineered batch ovens.

|  |

1. Robust drying chamber: Welded structural steel framework for overall support

2. Temperature uniformity: Typically the airflow within the heated chamber is designed with a recirculating horizontal cross-flow. They can also be equipped with a combination airflow pattern, top-down or bottom-up airflow pattern to guarantee temperature uniformity.

3. Rotary rack/shelf: Specially designed rotary rack/Shelf for Teflon parts can considerably increase heating uniformity.

4. Flexibility in heat source: Our batch ovens offer various heating methods, including gas, electric, infrared, and radiant heating systems.

5. Flexibility in operation: Numerous flooring options are available such as recessed tracks to accommodate product carts, a steel plate floor, or an insulated floor without tracks. Doors can be designed to accommodate any requirement and range from simple horizontal swing doors to pneumatic or hydraulic vertical doors with manual or automatic operation.

6. Easy and accurate control: Simple digital controls for basic operation or PLC controls for complex requirements

| Main specification | ||||

| Oven working space | Standard size or as per client requirement | |||

| Construction material | Mild steel; SUS304/316 or any | |||

| Working temp. range | Ambient+10 to 450 ℃ | |||

| Air-flow pattern | Horizontal / Vertical / combination | |||

| Temp. control accuracy | ±1℃ | |||

| Temp. uniformity | ±2℃ | |||

| Heat-up rate | RT-400 ℃ in 30 minutes | |||

| Timer | Digital pre-settable HS48S-99.99 | |||

| Paint | Enamel paint / Epoxy coating / powder coated | |||

| Power supply | 240V/380V/415V; 50Hz/60Hz; 3 phase | |||

| Heating elements | sheathed heating elements / SS tube | |||

| Insulation | Ceramic wool | |||

| Door seal gasket | Fibre glass rope | |||

| Heavy-duty rack/cart/tray | Designed according to product size, quantity and working condition | |||

| Exhaust manual or automatic | Automatic forced exhaust system with fresh air inlet Manually adjustable damper with fresh air inlet | |||

| Heat source | Electric or gas | |||

| Temperature control | PID with SSR/SCR for high accuracy With 40 programable heat-up rates | |||

| Temperature recorder (Optional) | Microprocessor chip-based paper less, multi-stage temp. indicator cum recorder | |||

| PLC with HMI ( Optional) | PLC can be provided for automation and integration of the whole system, data feeding, process display and fault indication can be seen in HMI | |||

| SCADA system (Optional) | High quality integration and controlling system from one point can be done with SCADA | |||

| Door (Optional) | 1) Door interlocked with fan and heater for safty 2) Doors on both ends 3) Vertical lift door | |||

| Windows and lights | 1) Viewing window 2) Interior light and access ports for calibration | |||

| Timer and alarm | 1) 24/7 timer 2) APT/AD16 audible / visual alarm indicators | |||

Rotary discs

Rotary tray

Inert gas oven

Heavy-duty rack with rail

PTFE Parts

PTFE plates

PTFE bars

A: Our Sintering oven can be customerized. Before we can work out a detailed quotation, we have to know the following information:

1) Type of heat process: drying, preheating, curing, sintering, forming, aging etc.

2) Product name, size, weight, quantity

3) Max temperature, heat-up rate, temperature uniformity

4) Construction material

5) Heat source

A: The dryer is packed in plywood box for shipping

A: We have the following standard models:

| Model | TY151-1 | TY-151-2 | TY-151-3 | TY-151-4 |

| Working space mm | 800X800X1000 | 1000X1000X1000 | 1200X1200X1100 | 1400X1400X1000 |

| Overall dimension mm | 1100X1560X1800 | 1300X1760X1800 | 1500X1960X1900 | 1700X2160X1900 |

| Tray diameter mm | 700 | 900 | 1100 | 1200 |

| Supply Voltage V | 240/380/415V | 240/380/415V | 240/380/415V | 240/380/415V |

| Electrical heater KW | 14 | 16 | 18 | 20 |

| Working temp. ℃ | RT+10 - 450 | RT+10 - 450 | RT+10 - 450 | RT+10 - 450 |

| Temp. control accucary ℃ | ±1 | ±1 | ±1 | ±1 |

| Circulation fan KW | 0.75 x2 | 0.75 x2 | 0.75 x2 | 0.75 x2 |

Drum dryer or roller dryer is an unique drying method for microalgae slurry with low energy consumption.

Dip feed drum dryer is specially designed for drying liquid raw materials, such as brewer's yeast, fruits and vegetable pulps etc with low energy consumption.

Agitator dryer is a simple fluid-bed type dryer with ribbon agitator, which is specially designed for drying mealworms with affordable price.

Agitator dryer is a simple fluid-bed type dryer with ribbon agitator, which is specially designed for drying fly maggots with affordable price.

Agitator dryer is a simple fluid-bed type dryer with ribbon agitator, which is specially designed for drying BSF larvae with affordable price.

V-shell blender is most often used for the intimate mixing of free flowing solids in food, chemical and pharmaceutical industries.

Vacuum shaft tray dryer is an ideal way for drying fresh bay laurel leaves without damaging the original flavors and color because of low-temperature drying process.

Vacuum shaft tray dryer is an ideal way for drying fresh bay laurel leaves without damaging the original flavors and color because of low-temperature drying process.

Batch Tumble Reactor is commonly used for solid-state post-condensation (SSP) of polyamide and polyester pellets (or flakes) for increasing IV value.

Agitator dryer is a simple fluid-bed type dryer with ribbon agitator, which is specially designed for drying BSF larvae (or maggots, larvae insects) with affordable price.

Vacuum Disc Dryer is a good way for drying fresh BSF larvae maggots to get high-quality dried product via low-temperature and vacuum drying process.

Paddle dryer is commonly used for continuously drying sewage sludge or biosolids due to high thermal efficiency, compact size, small off-gas flow and easy operation.

Vacuum Paddle Dryer with hot water heat pump has been increasingly used for drying various kinds of sludge due to low temperature drying, low energy consumption and zero emission working condition.

Double shaft paddle dryer is a high-efficient, mechanically agitated, indirect-heating drying processor which is commonly used for drying industrial sludge, sewage sludge, animal manure and other biosolids.

Low temperature vacuum drying is the key factor to protect the nutritional ingredients and original color of food products. Vacuum disc dryer is a very good drying method for soy pulp okara or other food byproducts due to low temperature and high-efficient drying process.

Vacuum Disc Paddle Dryer has been increasingly used for drying various kinds of sludge due to low temperature drying, low energy consumption and zero emission working condition.

WHAT YOU NEED TO KNOW ABOUT PREVENTION AND CONTROL OF NOVEL CORONAVIRUS DISEASE(COVID-19)